Press Releases

Innovation Meets Pharmaceuticals – groninger at the CPHI 2024 in Milan

The CPHI, one of the most important international platforms for the pharmaceutical industry, will take place in Milan, Italy this year from October 8 to 10, and will once again bring together the leading companies in the industry. groninger will be represented in Hall 18 at Stand A33 to present its machine concepts for the safe processing of small and medium production volumes on around 100 square meters.

Dirk Schuster, Sales Manager of the pharmaceutical division at groninger, emphasizes the importance of this trade fair: “The CPHI has made a name for itself as a central meeting place for exchanging information about industry trends and future-oriented technologies.” The quality of the discussions and the impulses gained are enormously valuable for both visitors and exhibitors.”

This year, groninger is focusing on the increasing importance of small and medium batch sizes in the pharmaceutical industry. “The demand for specialized solutions, especially in biotechnology, has increased massively in recent years,” explains Schuster. Biotechnological applications, often tailored to individual patients, require special systems that offer both flexibility and the highest precision.

“Such personalized therapies are revolutionizing healthcare by addressing the genetic and molecular characteristics of patients and, consequently making treatments more efficient,” explains Schuster. This poses new challenges not only for the pharmaceutical industry, but also for manufacturers of filling and packaging lines. While blockbuster drugs used to be produced in large quantities, today the focus is increasingly on very small, small and medium-sized batches, which must be processed just as efficiently and safely.

groninger responded to this trend early on and developed innovative machine concepts that will be on display at CPHI 2024. These include modules from the “labworx” series, which map the entire filling and closing process on semi-automatic table machines. These machines use the same technologies and components as groninger’s high-speed lines and enable seamless scaling of laboratory tests to industrial production quantities.

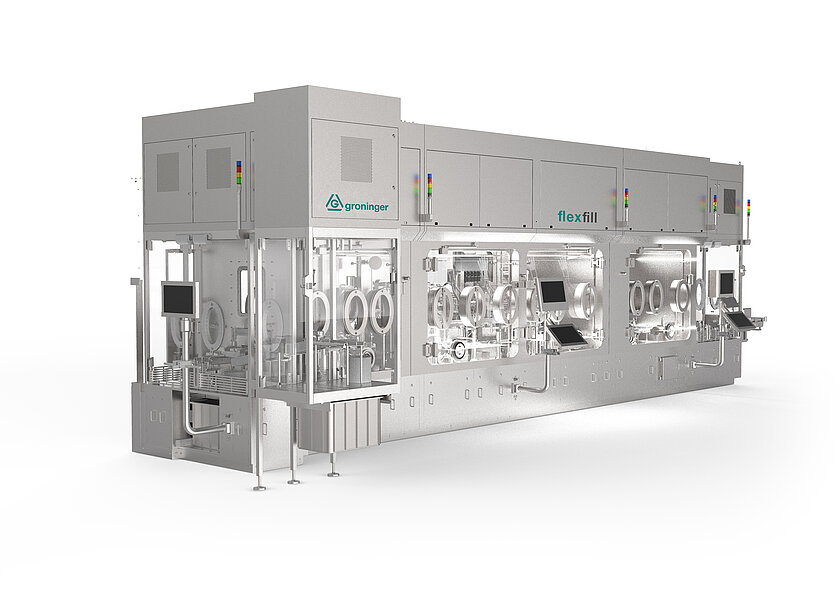

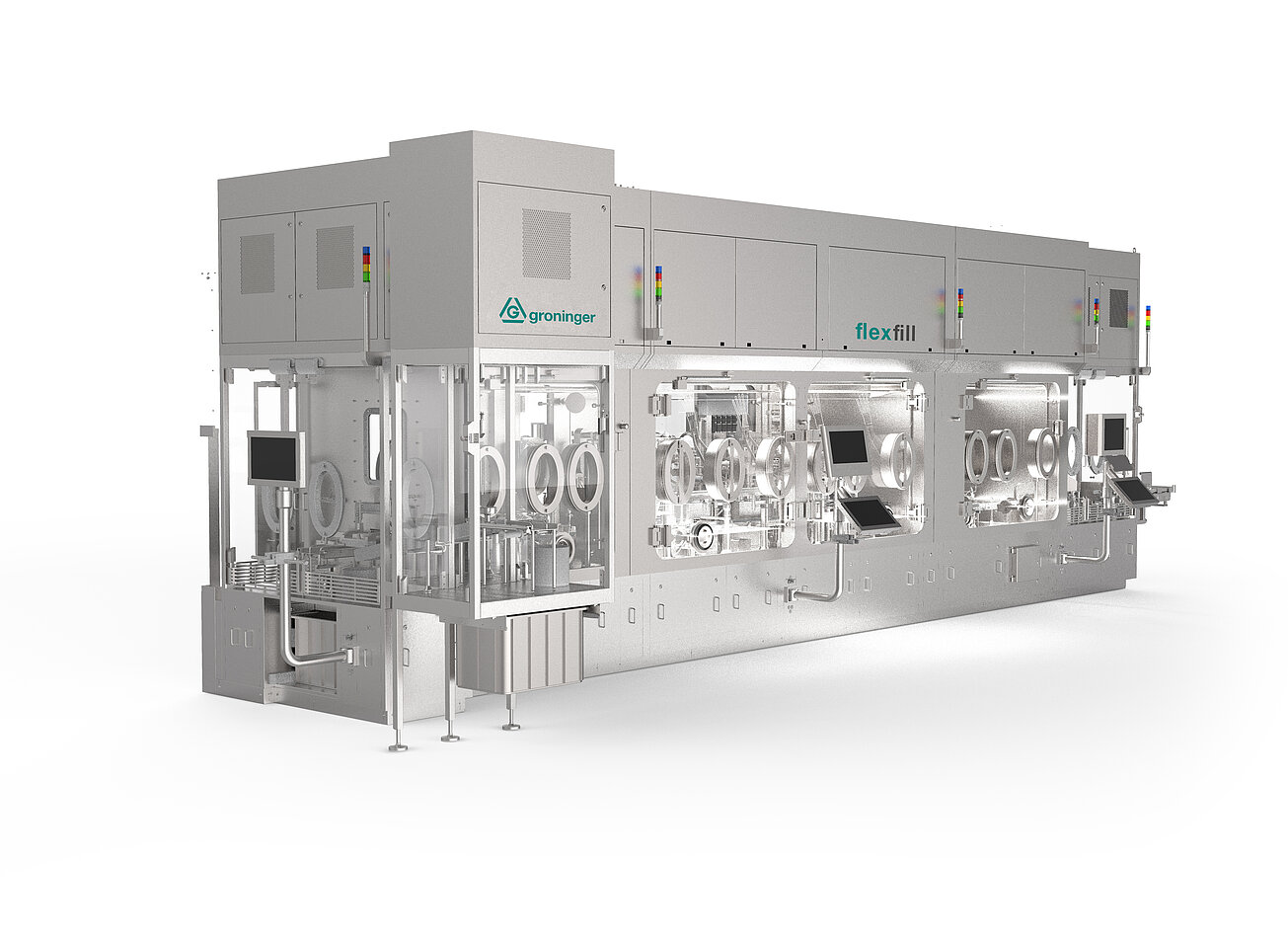

The flexfill will also be presented - a modular system concept that offers maximum flexibility for processing a wide variety of containers and product volumes. The flexfill line allows for the most accurate and efficient processing of various formats and materials. It is specifically designed to meet the needs of smaller batches. Thanks to its modular design, the line can be adapted to new requirements at any time, which is a great advantage, particularly, for research institutions and manufacturers who have to react quickly to market changes.

Another highlight at the groninger stand is the robocell. This is an award-winning gloveless machine concept that was brought to market in collaboration with the partner company SKAN, a specialist in isolator technology, and in which the pharmaceutical processing process was consistently rethought - explicitly taking into account all regulatory and official requirements of the industry. The result: a machine concept that uses robotic solutions intelligently. And always when they make the pharmaceutical process safer, more efficient and more flexible.

“Reliable cooperation with established partners is extremely important to us,” emphasizes Jens Groninger, Managing Partner, in this context and adds: “Our customers expect from us - and rightly so - optimal interfaces and a perfectly coordinated interplay of processes and functions on our lines.” Because solutions from a single source are demanded now more than ever. “We have evolved from a classic special machine builder to a specialist for system solutions.”

“With the help of our exhibitions, we are able to demonstrate which cutting-edge pharmaceutical processing methods are currently feasible for small and medium-sized batches without sacrificing quality or safety,” summarizes Dirk Schuster, adding: “We are pleased to present these to our customers, partners and companions.”